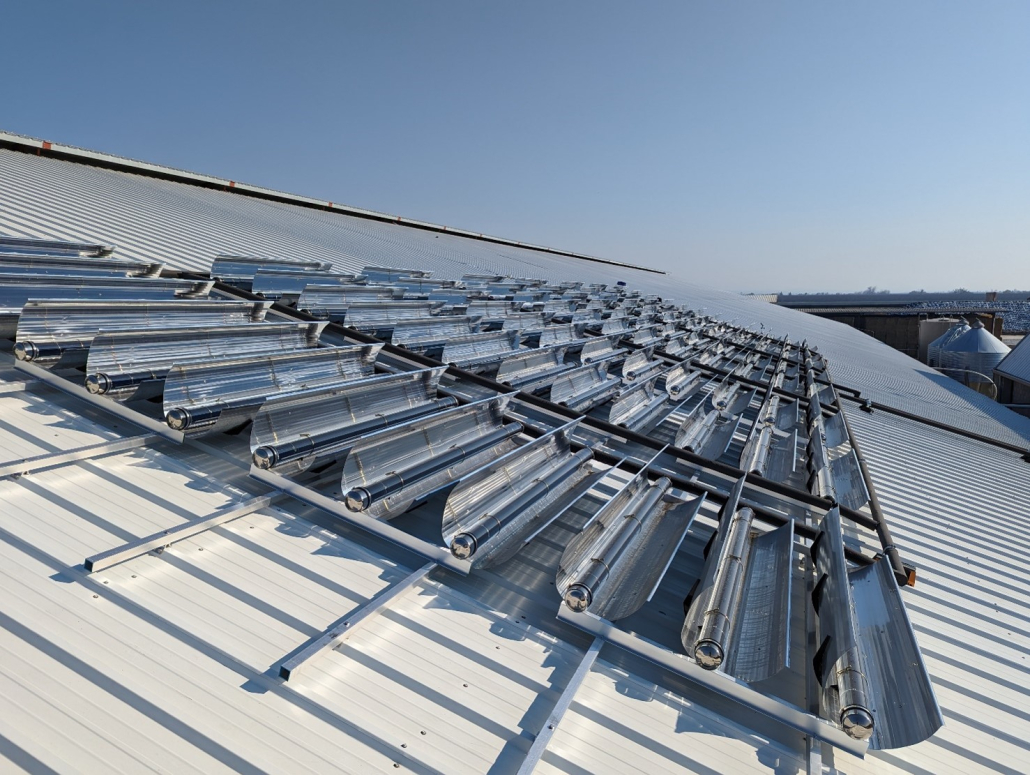

Winston Cone Optics’ installed pilot system on the roof of a dairy barn in California.

By Anna Adair, NCAT Energy Program Assistant

Thanks to the increase of solar photovoltaic sites in recent years, agrivoltaics has started to work its way into the public eye as a means of bridging the gap between land use for agricultural and energy production. By co-locating energy production with sustainable agriculture, the land that solar arrays occupy can continue to produce crops, provide forage for grazing animals, or even serve as a pollinator habitat for bees. Beyond photovoltaics, the broader umbrella of “agrisolar” also encompasses concentrated solar-thermal power (CSP), which can help decarbonize the agricultural processing space. Winston Cone Optics (WCO) in Merced, California, is at the forefront of this effort, helping dairy farmers reduce their propane consumption by using CSP to heat water for equipment sterilization.

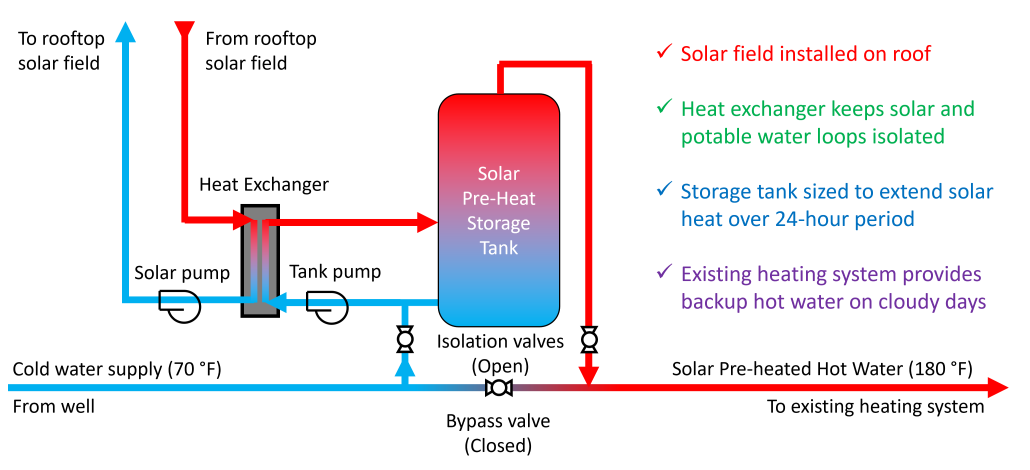

WCO’s CSP system was developed at University of California, Merced under the guidance of Dr. Roland Winston. The technology utilizes nonimaging optics, which allows the system to function in a stationary position. Compared to photovoltaic tracking systems – which adjust the solar panel’s angle throughout the day to follow the path of the sun – WCO’s system requires less upkeep and fewer parts, while simultaneously achieving 50 to 60% efficiency. The solar collectors pair nonimaging reflectors with evacuated tube receivers. These receiver tubes house a selectively coated fin that absorbs the concentrated thermal energy. As the fin increases in temperature, pressurized water is circulated through the tube and into a heat exchanger where the hot water can be passed into the hot water system.

Schematic drawing of the dairy’s system.

When WCO was looking for a pilot site, they learned of a local dairy building a fully automated freestall barn just down the road from their headquarters. They reached out to the farmer and offered to install their system in an effort to cut down the farm’s propane costs. Funding from California Energy Commission helped finance the project, which totaled around $50,000 not including labor. In October 2022, a 91-square-meter array mounted on the roof of the barn began pre-heating water for milking equipment sterilization. The system preheats 1,000 gallons of well water from 70 to 180 degrees Fahrenheit each day and collects it for use at any time in a hot water storage tank. It integrates seamlessly into the existing propane-fueled heating system, which now acts as a backup system to heat the water on cloudy days when the solar system can’t fully handle the demand. The system’s cost per kilowatt is almost half of what the farmer currently pays for propane, and it has reduced on-farm consumption for water heating by 70%.

Close-up of the concentrated solar system on the barn roof.

As farmers continue to search for ways to lower their operating costs and decrease their reliance on fossil fuels, WCO’s robust and uncomplicated system is an attractive solution showing great promise. The team emphasizes the adaptability of the system, as the modular collectors can easily be scaled up or down to meet the needs of a wide variety of processes. The modules are able to be installed on both flat and angled surfaces, making them easy to place on almost any rooftop and avoid taking up valuable ground space. The installation time is also impressively quick. The team first recommends conducting a thermal energy audit to ensure the building is properly insulated, followed by a period of time tracking the energy needs of the building’s current system. Once an understanding of the energy load has been established, the team knows how to size the CSP system properly for the process’s demands. Then, it may take as little as a few weeks to install the new system. Looking forward, the WCO team is excited to continue their work in the dairy space and hopes to expand their portfolio of sites across a variety of farms both big and small.

Photos courtesy of: Winston Cone Optics